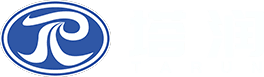

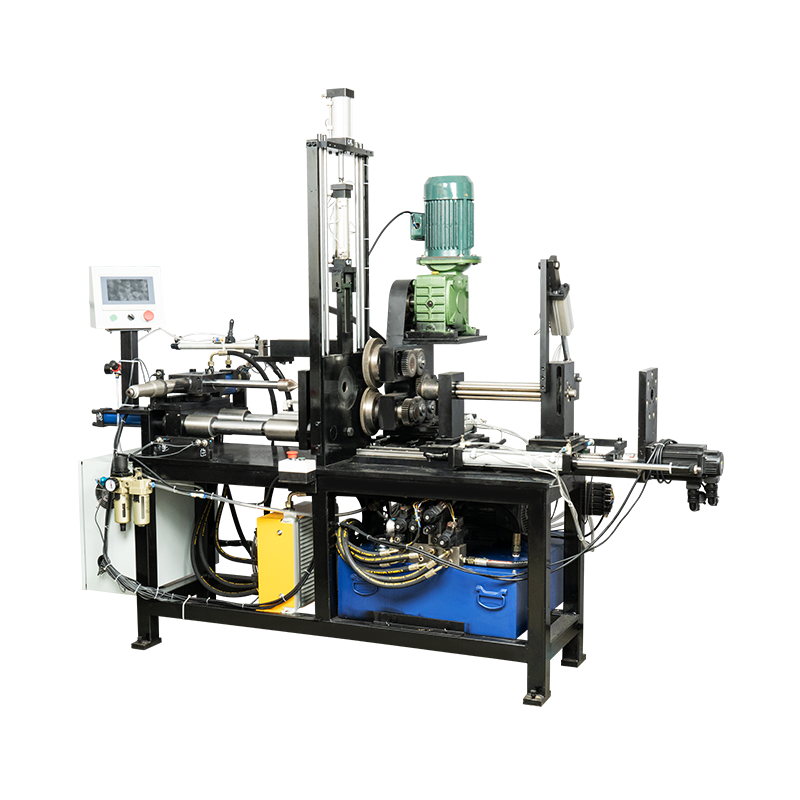

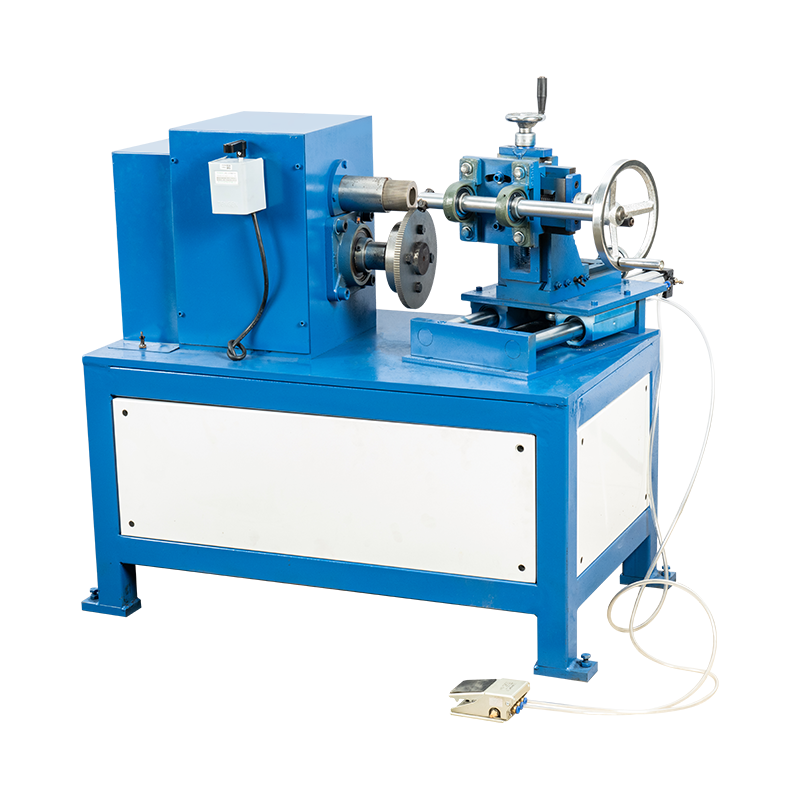

A nonwoven bonding machine is a highly specialized piece of equipment designed to apply adhesive and sand to nonwoven fabrics in a controlled and efficient manner. These machines are vital to every industry that uses nonwoven materials. By automating the bonding and gluing process, they help ensure adhesive consistency, high production speeds, and reduced material waste.

Product Benefits

Increase Production Speed

By automating the bonding process, this machine can significantly increase production speeds compared to manual methods. It can help manufacturers meet high demands more efficiently, reduce bottlenecks in production lines, and increase overall productivity.

Consistent Quality

One of the main benefits of nonwoven gluing machines is the uniformity of adhesive distribution it provides. The machine ensures that each batch of products meets the same high-quality standards, eliminating the variations that can occur during the manual gluing process.

Cost-effective

By reducing adhesive waste and labor requirements, gluing machines help reduce production costs. Its automated operation minimizes the need for extensive manual labor, saving time and manpower.

Product Features

Adjustable Gluing Settings

The machine allows for adjustable gluing settings, giving the operator the flexibility to change the amount of glue based on the specific requirements of the fabric and the end product. This feature makes it suitable for all types of nonwoven materials, whether they require light or heavy adhesive coverage.

Precision Gluing Technology

The machine is equipped with advanced gluing technology to ensure that adhesive is applied accurately to the designated areas of the fabric. This reduces the possibility of excess adhesive, which can cause production defects or increased material costs.

Automatic Glue Recovery

Some models are equipped with an automatic glue recovery system to help recycle excess glue during the production process. This feature minimizes waste and ensures that glue is used as efficiently as possible, further reducing costs for manufacturers.

Rugged and Durable Design

The nonwoven gluing machine is made of high-quality materials to withstand continuous use in demanding production environments. Its durable design ensures long-term reliability and reduces the need for frequent maintenance.

User-Friendly Interface

The machine is designed with a user-friendly interface, allowing operators to easily set parameters and monitor the performance of the machine. This simplifies the training process and helps operators maintain efficient production without complex adjustments.

Energy Efficiency

Modern nonwoven gluing machines are designed to be energy-efficient, helping to reduce operating costs. These machines optimize energy consumption while maintaining consistent and high-quality performance, making them a cost-effective solution for large-scale production.

The machine’s flexibility, energy efficiency, and automation features make it a valuable investment for businesses looking to streamline their production processes and increase profitability.

English

English 中文简体

中文简体 Español

Español