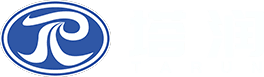

The Precision CNC Hydraulic Cutting Machine is a high-performance cutting tool designed for industrial use, offering precision and efficiency in cutting metal materials, particularly for wire processing.

Product Advantages

High Efficiency

The Precision CNC Hydraulic Cutting Machine operates at high speeds, significantly improving production rates. The combination of CNC control and hydraulic pressure allows for swift and accurate cuts, making the machine ideal for large-scale production environments. By reducing cycle times and enhancing throughput, the machine helps manufacturers meet demanding deadlines while maintaining consistency in product quality.

Low Operational Costs

This cutting machine is designed to minimize operational costs through efficient power use and reduced material waste. The hydraulic system ensures that cutting force is applied precisely, reducing unnecessary consumption of energy. Additionally, the machine’s precision cuts minimize scrap material, optimizing the use of raw materials and contributing to lower costs. The long-term durability and reliability of the system also result in lower maintenance and repair expenses, further decreasing operational costs.

Consistent Product Quality

Precision and consistency are critical in industrial cutting, and the CNC hydraulic cutting machine excels in both areas. The machine ensures that every cut is made with high accuracy, providing uniform results throughout the production cycle. This consistency is essential for industries that require standardized products, such as wire brush manufacturing, where the precision of each wire segment directly impacts the quality of the final product.

Product Features

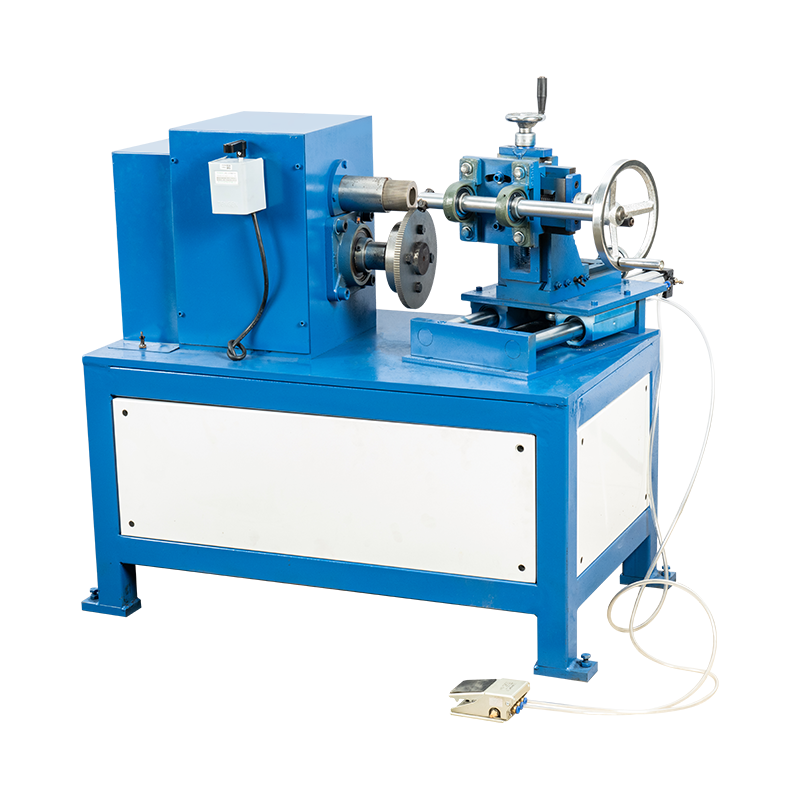

Advanced Control System

This system allows for precise adjustments in cutting length, angle, and positioning, accommodating a wide range of cutting requirements.

Hydraulic Pressure System

The integrated hydraulic system delivers consistent cutting power, ensuring that even tough materials are processed smoothly. The hydraulic mechanism applies uniform pressure to the wire, allowing for clean, smooth cuts that prevent material distortion. This feature is particularly beneficial when working with high-tensile wire and other challenging materials, as it ensures reliable results with minimal wear on the cutting components.

User-Friendly Interface

The machine is equipped with an intuitive control interface that simplifies the operation process. The clear digital display and easy-to-navigate menu enable operators to adjust settings quickly and accurately, improving the overall user experience. This user-friendly design reduces setup time and enhances operational efficiency, especially in fast-paced production environments.

Durable and Low-Maintenance Design

Its robust design ensures reliable performance even under continuous use, making it suitable for high-volume operations. Additionally, the machine is designed for easy maintenance, with accessible parts and minimal servicing requirements, further increasing its long-term value.

Product Applications

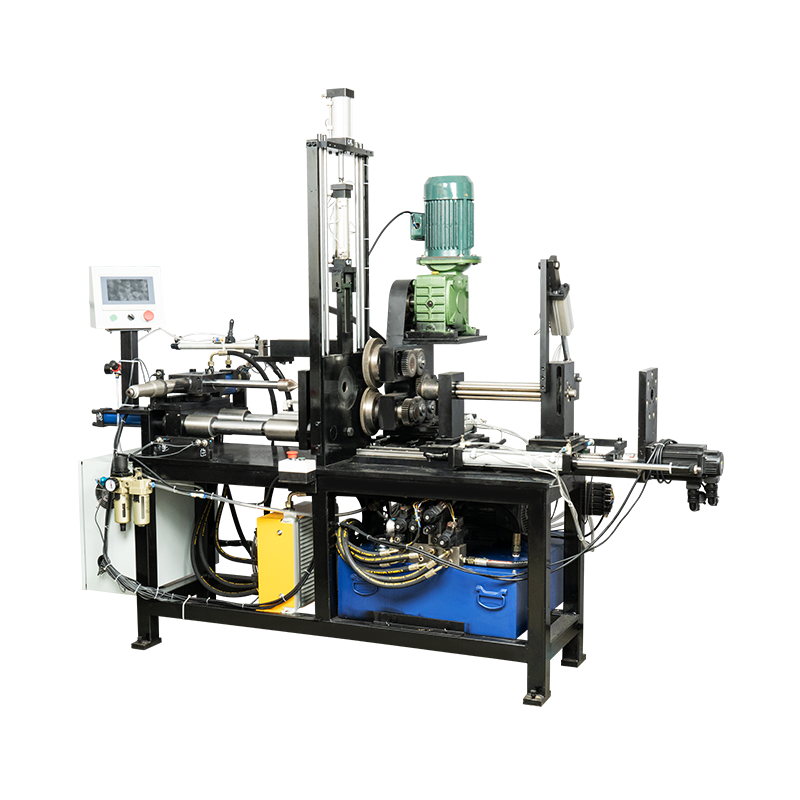

Wire Brush Manufacturing

The Precision CNC Hydraulic Cutting Machine is primarily used in the production of wire segments for wire brushes. The machine cuts metal wire into uniform lengths that are then used to create the bristles of wire brushes. These brushes are used in a variety of industries, including automotive, cleaning, and metalworking. The machine’s precision ensures that each wire segment meets the required specifications, resulting in high-quality brushes with consistent performance.

Metal Cutting and Fabrication

In addition to wire brush manufacturing, the machine is widely used in other metal cutting and fabrication applications. The machine can be used to cut metal wire and rods into specific lengths for use in various products, such as components for machinery, automotive parts, and structural elements in construction. The precision cutting capability makes it valuable for any industry that requires high-accuracy cuts for metal materials.

English

English 中文简体

中文简体 Español

Español